Commercial structure fixing is not a singular trade. It is actually ground auto mechanics, building actions, gain access to strategies, as well as service provider judgment conference within inches of an existing property that commonly can not turn off. When resolution telegrams by means of slab joints, when a cantilevered exterior stoops with seasonal cycles, or even when a keeping wall structure starts to bend, the cure is actually rarely one item. It is a body that mixtures helical anchors, tieback anchors, and also micropiles with a fixing strategy that recognizes the building's tons pathway and the website's constraints.

I learned this beforehand while maintaining a mid-century health care office along with differential settlement deal over 1.75 ins around a 90-foot operate. The geotechnical file reviewed like a pile of alerts: loose filler to 12 feet, delicate sands to 28 feets, a sparse sand lens, then thick antarctic till. Our company wound up incorporating helical piles along the perimeter along with a series of internal micropiles through piece positions, linked to brand-new grade shafts. Business always kept operating. Clients kept arriving. And also the property ceased moving. That mix is actually where commercial foundation stabilization truly lives.

Where helical anchors as well as micropiles fit

Helical anchors and also micropiles are each deep groundwork aspects, but they deal with various complications and also they act differently in soil.

Helical heaps and helical tieback anchors are actually torque-installed steel arrows along with several coil plates that birth in proficient dirts. We quantify capacity coming from installation twist utilizing a connection element, then verify with evidence or confirmation examinations. They master compressive assistance for underpinning and also in side restriction when made use of as tieback anchors. Specialists like them for websites along with limited space and also low resonance. In commercial helical pile installation, our team may surgically incorporate capacity under an active structure, one column line at a time, along with very little mess.

Micropiles are small-diameter drilled and grouted heaps, generally along with steel support such as a bar or an examined area. They establish capacity through grout-to-ground bond and also side bearing if our company backside them in dense component or even rock. Micropile installation endures changeable soils and impediments. In commercial Commercial Helical Pile Installation micro pile installation, our team can serpent gears right into cellars https://www.unitedstructuralsystems.com/free-guide/ and also tight hallways as well as achieve midsts that helical piles can easily not practically get to when overburden is gentle or even cobbly.

The pairing is actually powerful. Helical piles activate ability promptly as well as enable instant payload transmission, usually the exact same day. Micropiles deal with much higher lots per component, overcome fill with clutter or collapsed joints, and shine in seismic retrofits where downdrag and also periodic demands complicate design.

Reading the ground as well as the structure

Soil governs the resource. Structure dictates the particulars. A couple of examples emphasize the choices.

- A single-story tilt-up stockroom with a settled edge slab through 1 to 1.5 inches, remaining on undocumented fill over heavy sand. Helical piles make sense. We can easily twist through the stuffing, chase after the rich sand, and also underpin the section along with brackets to elevate and also latch it. If we encounter a tense layer at, mention, 18 to 22 feets with twist going up towards refusal, our team can easily quit with higher assurance in capacity. A four-story block office along with a cellar as well as a pitching soldier stack wall structure. The soil profile shows interbedded residues, lens of sand, and spread boulders. The kept dirt uses sidewise stress that keeps creeping. Helical tieback anchors will certainly face obstruction dangers. Micropile tiebacks, taught along with down-the-hole hammers or duplex strategies, may be much safer to connect with the rock joint and make a reputable connection zone. Alternatively, our team utilize commercial helical tieback anchor installation where our experts may captain around boulders and also evidence exam each anchor, allowing some rejections and also redesigning on the fly. A health care facility expansion along with inadequate fill and also energy congestion, target column lots of 400 to 600 kips, limited clearance, as well as vibration-sensitive tools. This indicates a hybrid: sets of micropiles for vertical capability under brand-new columns, paired with helical anchors for deriving surrounding existing wall surfaces with lighter lots of 40 to 80 kips per heap. The micropiles take the hefty hauling. The helical piles maintain the existing footprint along with marginal disturbance.

These are not hypotheticals. They present why commercial foundation repair frequently integrates numerous deep elements instead of betting on one.

The technicians of capacity, along with varieties that matter

For helical piles, our experts begin along with the individual bearing ability of helix plates. Setup twist is our field pressure indicator. A typical relationship makes use of a torque relationship variable, Kt, often in between 8 and also 12 for square ray as well as around shaft bodies, depending upon producer screening and ray geometry. If our team install a round-shaft helical pile and finish at 6,000 foot-pounds of twist along with Kt of 10, the permitted squeezing capability through torque could be on the order of 60 kips just before using protection factors and also use requirements. We confirm via strain or squeezing testing, normally to 1.5 to 2 opportunities design load.

For micropiles, concept pays attention to connect stamina as well as steel capability. In a soft silt-clay with grout, layout connect might vary from 10 to 30 psi, while in heavy sand it might be 30 to 80 psi, as well as in rock one hundred to 300 psi or additional. A 6-inch cement pillar along with a 20-foot bond size in stone at 150 psi proposes around 47 kips every feet opportunities 20 feet, which is 940 kips supreme, thus permitted might be 300 to 500 kips depending upon variables, elevated screening, as well as tons scenarios. That shows why micropiles can easily carry massive columns even in tight spaces.

Tieback supports, helical or bored, rely upon totally free span prolongation as well as connection span anchorage. Evidence screening criteria are commonly 120 to 150 percent of design lots with tons keep standards on lock-off. Our company check out creep. If the support expands more than a tiny limit over a timed grip, it might suggest insufficient connection or even dirt leisure. Anchors that pass along with low creep motivate assurance even when the dirt variability would certainly make a geologist wince.

Where protection stacks belong

Commercial resistance pile setup refers to press boat docks, likewise called protection heaps, steered by the establishment's body weight. They radiate on deriving where we possess enough lifeless load to set in motion friction and edge bearing by pushing steel sections into the ground till our team reached experienced strata. They are actually quickly, require minimal spoils, and rely upon gas response. The catch is load. A softly packed wall can restrict setup power, which subsequently limits depth and capability. In those instances, our team may stage body weight, add brief reaction beams, or even switch to helical piles that perform not depend on establishment weight for installation.

On ventures with moderate loads as well as sensible get access to, resistance piles supply great value. For example, a retail strip along with 8-inch CMU wall surfaces as well as laminates decided on one point can easily typically be actually stabilized with resistance piles under brand-new braces, lifted fractionally, as well as latched off. The distinction between resistance pile and also helical pile selections typically boils down to soil harmony as well as structural reaction. When strike considers or even CPT soundings reveal a predictable thick layer within useful depth, protection stacks are actually a competitor. If filler density varies dramatically all over the operate, helical piles offer more control.

Foundation split repair work is certainly not the solution, it is the finish

Cracks in commercial pieces and walls narrate. Hairline map splitting could be contraction. A stair-step gap at a corner with matching slope improvement is actually settlement deal. Epoxy injection or even urethane injection can weaved a split as well as quit water leaks, however it will certainly not prevent movement unless our experts support the dirts and also establishment. When a customer seeks "foundation crack repair" on a building that is still relocating, the conversation rotates to fill course as well as ground assistance. Our company can infuse after our team derive, certainly not in the past. Typically, the fracture is going to reopen, or even worse, telegram brand new splits elsewhere.

I maintain pictures of a factory where our experts raised a settled piece edge through 0.9 ins along with helical piles and also piece brackets spaced at 6 to 8 feets, at that point ground as well as infused the residual fractures. The epoxy work looked sharp. More vital, the dial indicators check out no motion 6 months eventually after in season groundwater swings.

Sequencing without chaos

In commercial setups, down time costs cash. Sequencing is as a lot a component of structural foundation repair as the steel and grout.

First, confirm the geotechnical style. If the report is actually much older than a handful of years or even website modifications have actually occurred, budget for supplementary borings or even CPTs. Second, strategy exam factors. A proof helical pile or a pre-production micropile tells you whether the assumed bond durability or even twist relationship delays. Third, handle load transfer. Underpinning brackets require careful hoisting to stay clear of over-lifting. For columns, preloading is actually frequently essential to seat heaps as well as employ load.

On hospital and lab work, resonance as well as sound constraints push our team toward helical anchors and micropiles over steered steel. Electric torque electric motors and also small track rigs minimize disturbance. Third shift assistance. You know to stage spoils handle along with vac trucks as well as filter socks considering that examiners as well as next-door neighbors observe dirt run-off prior to they notice you maintained their block.

Design selections that matter in the field

Shaft variety for helical piles is actually certainly not aesthetic. Square shaft elements withstand strain successfully, yet could be prone in side tons and bending in soft soils. Round shaft bodies give much better rigidity as well as bending protection. If our company prepare for lateral loads, or even if the heap stretches with soft strata where fastening is a threat, we pick a round shaft or even a combo system along with shot leads and also straight extensions.

Helix configuration needs to have idea. A three-helix top with 10, 12, 14-inch plates spaced at 3 opportunities the dimension frequently supplies a well balanced load reveal. Too many platters in poor grounds may generate a plug that slows just before skilled material. Extremely handful of can underutilize a great coating. Along with helical tieback anchors, our experts target the helix collection past the energetic wedge. If a preserving wall is actually 12 shoes tall, the connect region typically starts 0.6 H to 0.8 H responsible for the wall structure's rear face, depending on ground rubbing as well as surcharge. That places coils where the soil is quiet.

For micropiles, bond length as well as covering decisions control efficiency. In collapsing dirts, permanent examining via the overburden prevents necking as well as contaminants of the cement column. Where lateral demands are non-trivial, our experts could raise casing span to incorporate bending over rigidity. Grout takes the connection, steel takes the flexing. If the tons scenario includes seismic uplift, our company specify centralizers and also make sure enough complimentary duration for flexible extension, so the pile behaves naturally under cycles.

Typical capabilities as well as when to blend systems

Commercial helical pile installment typically targets permitted loads coming from twenty to 120 kips every pile, with greater worths possible in strong grounds. Helical tieback anchors typically sit in the 15 to 80 kip variation every anchor, again depending upon dirt as well as coil size. Micropiles vary largely, coming from 40 kips on the reduced edge to many hundred kips every component in rock.

Mixing devices is actually not a trade-off; it is actually optimization. Consider a 1960s university with a fitness center add-on. The boundary bit footings lug moderate tons, however the new glulam roof covering trusses bear hefty responses at distinct factors. Our team could found the bits along with helical piles at 40 to 60 kips each, spaced tight, while we answer the truss reactions along with two to 4 micropiles per pad at 150 to 250 kips each. The combination conserves funds, has timetable danger, and deals with ability where it is needed.

Testing that protects against regret

Testing is actually certainly not optional in deep foundation repair. On helical piles, our experts proof exam an amount, usually 10 to twenty per-cent, to 1.5 times layout bunch. If torque-to-capacity correlation appears smooth, we readjust Kt or even ride deeper. For tieback anchors, evidence screening every support is common strategy, with lock-off at an aim at tons as well as an assessed elastic expansion that matches idea within affordable tolerance.

Micropiles ask for pre-production examinations to confirm bond worths, after that functionality tests on a subset to higher bunches. If an examination pile sneaks past acceptance at grip, our team boost connection length or button to a roughened covering method to enhance connection. It is far much cheaper to readjust on the test platform than to find a deficiency after the piece is actually back in position and operations resume.

Logistics and constructability, the genuine routine drivers

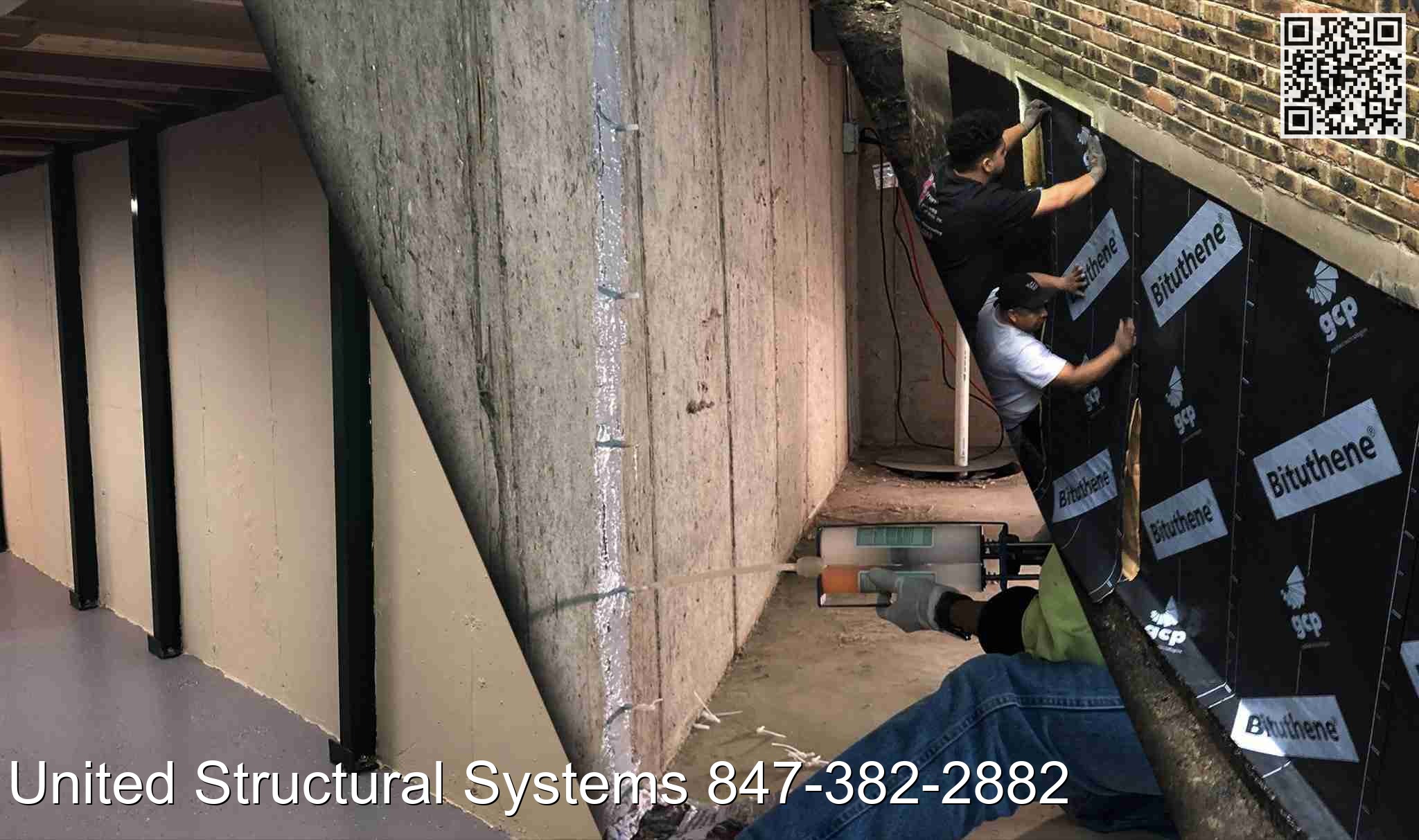

It is the main thing to design a micropile along with a 25-foot connection zone in dense sand. It is one more to get a drill rig right into a cellar along with a 7-foot-6-inch roof and no products escalator. Think about gear size, electrical power source, spoils elimination, water management, and venting. On commercial resistance pile installation, you need to have very clear response aspects and cautious shoring if the wall surface is compromised.

Helical supports create marginal spoils, however they perform need straight shot setup paths. In strict mechanical spaces, that implies moving equipment or even cutting momentary get access to windows in pillar wall structures. I have actually installed helical piles through floor observed cuts, at that point pruned new grade shafts under the slab, linking the pile hats in to the building. The job was actually unnoticeable when our experts left behind, which is what office clients prefer.

Water, rust, as well as durability

Groundwater makes complex everything. For helical piles, installation with waterlogged residues can wrap greats around the helix stack and reduce torque readings, creating ability prophecies much less trusted. We compensate along with much deeper embedment or bigger coils settled in cleaner levels. For micropiles, groundwater spurs careful tremie grouting from the idea up, ensuring total connection as well as staying away from partition. If inflow is significant, our experts might utilize studying to separate the connect region in the course of grout placement.

Corrosion protection depends upon soil chemical make up as well as style lifestyle. Helical anchors can be hot-dip driven or epoxy layered. Micropiles increase integral security coming from alkaline grout cover, but in aggressive grounds our company upsize bench or even studying for propitiatory density. In social infrastructure along with 75 to 100-year concept lifestyles, our team chronicle rust expectations rather than swing at all of them. It is actually less complicated to add 1/8 in of wall structure thickness abstractly than to take another look at a failing base three decades out.

Cost as well as schedule realities

Owners request for varieties. Generally, helical piles frequently deliver reduced expense every put in kip for small to medium bunches and also when accessibility is actually constricted yet not impossible. Micropiles carry greater unit price due to drilling, steel, and grout, however they can merge heavy loads in to far fewer aspects as well as get through geology that would certainly cease a helical workers. Tieback anchors in dirt are actually generally less costly than stone anchors, supplied connection spans are actually doable in experienced soils.

Schedule depends upon use and screening. Helical teams may mobilize rapidly and scoot the moment onsite. Micropile crews need to have additional configuration, water, cement mixing, and spoils monitoring. If the task tolerates a two-phase approach, start with the helical underpinning to support the construct, after that transfer to micropile setups for hefty points. That sequencing keeps obvious progression as well as decreases threat as dirts disclose themselves.

A quick guidebook to picking the correct element

Here is actually a concise contrast that grabs the point without over reducing:

- Helical heap: torque-installed, immediate capacity, minimal spoils, sensitive to clutter in fill, excellent in sands and also clays with steady coatings, usual for deriving and illumination to moderate loads. Helical tieback support: effective for retaining wall surface stablizing as well as sidewise restriction, proof checked individually, demands support installment past the active wedge. Micropile: drilled and also grouted, higher capability per component, deals with blockages and adjustable geography, ideal under hefty columns or even where deep-seated qualified component is far listed below grade. Resistance stack: pushed along with structure weight, easy install, cost-efficient for deriving when building provides ample reaction, a lot less foreseeable in very adjustable fill.

Case pictures that present the blend

A seaside lodging on heaps and also shallow charities displayed differential negotiation along an ocean-facing airfoil. The soils included loose dune sands over a firm layer. Our team put up commercial helical piles at 12-foot spacing below the border shaft, attacking ability at 5,500 to 7,000 foot-pounds and latching off at 40 to 60 kips per stack. At pair of staircase high rises along with much heavier tons and lateral drift from wind, our company shifted to micropiles with 15-foot bond spans in the concrete coating, checked to 200 kips. The structure stopped turning. The proprietor resumed that segment in front of peak season.

A distribution center with a 16-foot-high preserving wall surface bulged 2 ins at mid-height over 80 feets. Get access to responsible for the wall surface was actually shut out by a property line. Our experts did commercial helical tieback anchor installation coming from the inside, tilted anchors with cores in the wall surface panels, and also placed helix varieties past the academic failure wedge. Each anchor evidence tested to 130 percent of a 50-kip concept tons with very little creep. We added a continuous waler to distribute bunches and tensioned sequentially. The wall loosened up enough to finalize junctions yet, much more significantly, quit moving.

A historical cinema remodelling called for brand new roof mechanicals, incorporating tons to existing columns. The grounds included strong soft clays along with an occasional sand seam. Helical piles had a hard time to discover a reliable seat without excessive embedment. Our experts rotated to commercial micro pile installation, piercing 7-inch openings with casing through 35 feets of soft clay to a sand seam, then even further to weather-beaten rock. Grouted bars created connection in rock for twenty feets. Load examinations passed at 250 kips along with strict creep curves. The brand new rooftop systems went in, the acoustics continued to be peaceful, and also the timetable held.

Integration details that raise the repair

Deep elements just work as component of a payload road. That means cautious brace assortment under existing grounds, brand new quality beams that circulate tons to numerous heaps, and also components that fits eccentricities without overstressing the pile. On foundation, I choose braces with stout bearing seats and positive technical locks rather than relying solely on rubbing clamps.

For micropiles under pillars, heap hats must connect right into the column bottom with pegs and adequate progression. If the column observes sidewise lots, look at a cap with deepness as well as reinforcement that involves the stack flexing hardness. On helical tieback anchors, the waler or even deadman should be sized for the sum of support tons along with reasonable space. Spreading, wavering, and phasing tensioning avoids generating a brand new problem while handling the aged one.

Do certainly not forget negotiation compatibility. If a micropile assists a column and also adjacent strip footings sit on more mature shallow foundations, differential activity may appear later. Either derive the bit grounds along with helical piles at strategic aspects or approve as well as detail for a tiny action gradient with joints and also adaptable surfaces. Truthful conversations with the proprietor avoid surprises.

Quality control in the dust, certainly not simply on paper

Documentation in the course of installment produces or even damages the guarantee. Helical pile logs need to tape torque every deepness, helix arrangement, last embedment, and lock-off lots. Support screening logs ought to consist of tons actions, accommodate times, extensions, and also monitorings of creep. Micropile logs should record boring technique, dimension, connection size, cement mix, stress, and also take, along with bar or casing dimension and centralizer spacing.

I insist on pictures of every crucial action. The day you need to have to prove a stack got to 32 feet as well as not 22 feet, a crystal clear shot of the extension count and lead setting up is worth much more than any narrative. On one work, a missed out on centralizer resulted in eccentric pub placement as well as a dubious connection cover. We caught it and re-drilled pair of stacks before the cap was poured. That spared a forensic frustration a year later.

Safety as well as environmental restrictions you can certainly not prefer away

Confined spaces, above accidents, and silica dust are day-to-day realities. For micropiles, wet drilling lessens dirt yet creates slurry monitoring commitments. For helical piles, twist reactions may stun unskilled hands. Learn workers to avoid revolving cylinders and also to value twist tops. On protection piles, the jacking pressure may tear at braces if the footing concrete is actually poor. Our experts commonly potato chip to appear cement and utilize epoxy dowels to anchor braces, regardless of whether a producer delegation performs certainly not demand it. Industry health conditions defeat brochure pages.

Environmental allowing in some cases rests on spoils taking care of and also groundwater discharge. Planning restriction, sample if demanded, and steer clear of expectations that set you back improvement orders and also harmful will.

When to phone the geotech back in

Commercial base stablizing gain from a live geotechnical companion. If you attacked refusal very superficial on helical piles, if support creep is actually marginal, or even if micropile cement takes double the counted on quantity, cease and collect yourself along with the designer. A simple website see as well as a revised information can save a routine. I have actually changed coil diameters mid-project, lengthy connect durations by 5 to 10 feet, and exchanged pair of heap areas to avoid powers based on a mutual whiteboard illustration. That versatility is actually simply achievable when communication remains tight.

A sensible road forward

Every commercial foundation repair sits at the junction of geography, building, and service constraints. Helical anchors, helical piles, resistance stacks, and micropiles are resources that, when blended attentively, supply secure, foreseeable functionality. Avoid the appeal of single-solution reasoning. Beginning along with a crystal clear geotechnical image, style for realistic capacities, test sufficient to feel great, and integrate the elements along with correct weight pathways and also outlining. Foundation crack repair fits, yet simply after stablizing. Proprietors value repair services that disappear right into the structure's routine, leaving no dramatization and also no callbacks.

If your internet site mean delicate clays, adjustable stuffing, or even tough incorporations, plan on combinationing devices. Commercial helical pile installation excels at silent, quick foundation. Commercial resistance pile installation may be the spending plan hero for wall structures as well as lighter frameworks with adequate significance to press. Commercial micro pile installation supplies higher ability in tight areas and difficult dirts. Commercial helical tieback anchor installation maintains wall surfaces without rear accessibility and evidence tests safely. All together, they rotate unclear ground right into reputable support.

The greatest compliment I have listened to arised from a superintendent six months after our experts finished a crossbreed deep foundation repair under an energetic university. He said the building really felt sound once again. Not a technical statistics, however specifically the result our team intend for.